How Perforated Anti-Slip Plates Enhance Metal Processing Efficiency

2025-10-17

How Perforated Anti-Slip Plates Enhance Metal Processing Efficiency

Table of Contents

Introduction to Perforated Anti-Slip Plates

The Importance of Metal Processing Efficiency

Design Features of Perforated Anti-Slip Plates

Applications in Metal Processing

Benefits of Using Perforated Anti-Slip Plates

Enhancing Workplace Safety

Cost-Effectiveness and Longevity

Insta

How Perforated Anti-Slip Plates Enhance Metal Processing Efficiency

Table of Contents

- Introduction to Perforated Anti-Slip Plates

- The Importance of Metal Processing Efficiency

- Design Features of Perforated Anti-Slip Plates

- Applications in Metal Processing

- Benefits of Using Perforated Anti-Slip Plates

- Enhancing Workplace Safety

- Cost-Effectiveness and Longevity

- Installation and Maintenance

- Conclusion

- Frequently Asked Questions (FAQs)

Introduction to Perforated Anti-Slip Plates

In the fast-paced world of metal processing, maintaining efficiency while ensuring safety is paramount. Among various innovations that aid this balance, **perforated anti-slip plates** stand out as crucial components. These plates not only enhance productivity by providing a secure footing for workers but also streamline operations in manufacturing settings. Understanding how these plates function and their importance can significantly impact operational efficiency.

The Importance of Metal Processing Efficiency

Metal processing efficiency plays a vital role in the manufacturing sector. It encompasses various aspects such as material handling, production speed, and worker safety. Improved efficiency leads to reduced operational costs, higher output, and better quality control. As manufacturers strive to optimize their processes, introducing elements like perforated anti-slip plates can revolutionize their operational strategies.

The Role of Efficiency in Manufacturing

In the competitive landscape of manufacturing, efficiency translates into profitability. High operational efficiency allows manufacturers to respond swiftly to market demands without compromising quality. Perforated anti-slip plates contribute to this efficiency by minimizing slips and falls, ensuring that workers can operate machinery and handle materials with confidence.

Design Features of Perforated Anti-Slip Plates

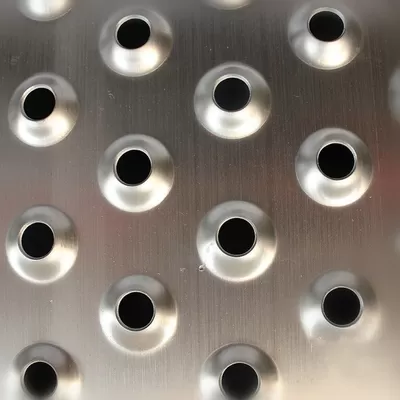

The design of perforated anti-slip plates is a testament to engineering excellence. These plates typically feature a series of holes strategically placed to enhance traction while maintaining structural integrity.

Material Selection

Manufacturers often choose high-grade materials such as stainless steel or aluminum for durability and corrosion resistance. This selection ensures that the plates can withstand harsh working environments typical in metal processing.

Customizability

Another significant design aspect is the ability to customize these plates to fit specific applications. Whether it's for a large industrial press or a smaller machining area, perforated anti-slip plates can be tailored to meet diverse requirements.

Applications in Metal Processing

Perforated anti-slip plates find use in various areas within metal processing facilities. Their versatility makes them suitable for several applications, including:

Machinery Platforms

Platforms equipped with perforated anti-slip plates provide a safe and stable surface for operators working with heavy machinery. This setup enhances control and reduces the likelihood of accidents.

Walkways and Workstations

In busy manufacturing environments, ensuring that walkways and workstations are safe is crucial. Installing perforated anti-slip plates in these areas can significantly reduce slipping hazards, fostering a safer workplace.

Material Handling Areas

The areas where raw materials are handled can be prone to spills and accidents. Perforated anti-slip plates can help manage these risks by providing a slip-resistant surface, enhancing both safety and efficiency.

Benefits of Using Perforated Anti-Slip Plates

The integration of perforated anti-slip plates in metal processing operations offers numerous benefits that extend beyond safety.

Enhanced Traction

The perforated design of these plates ensures maximum grip, even in slick conditions. This feature is crucial for preventing slips and falls, particularly in environments where oils and lubricants are present.

Increased Productivity

By creating a safer working environment, workers can operate machinery with greater confidence and efficiency. This boost in productivity can lead to significant improvements in overall manufacturing output.

Durability and Longevity

High-quality materials used in the construction of perforated anti-slip plates ensure that they can withstand the rigors of metal processing. Their durability translates to lower replacement costs over time.

Easy Maintenance

Maintaining these plates is relatively simple. Regular cleaning and inspections can keep them in optimal condition, ensuring continued safety and efficiency.

Enhancing Workplace Safety

Safety in the workplace is non-negotiable, especially in industries like metal processing where the risks are higher. Perforated anti-slip plates significantly enhance workplace safety by:

Reducing Slip and Fall Risks

The primary function of these plates is to provide a non-slip surface, thus greatly reducing the chances of slips and falls. Proper installation and maintenance of these plates can lead to a marked decrease in workplace accidents.

Complying with Safety Regulations

Adhering to safety regulations is essential for any manufacturing facility. Utilizing perforated anti-slip plates helps ensure compliance with local and international safety standards, protecting both employees and the company.

Cost-Effectiveness and Longevity

Investing in perforated anti-slip plates may seem like an upfront expense, but the long-term savings can be substantial.

Reduced Healthcare Costs

By minimizing workplace accidents, companies can significantly lower healthcare costs associated with employee injuries. This financial benefit extends to reduced insurance premiums as well.

Longevity of Equipment

The added safety and stability provided by these plates can also prolong the life of machinery and equipment by preventing unforeseen accidents that could result in costly repairs or replacements.

Installation and Maintenance

Installing perforated anti-slip plates is a straightforward process, but it requires careful planning and execution.

Installation Steps

1. **Site Assessment**: Evaluate the specific areas where the plates will be installed to ensure proper fit and function.

2. **Preparation**: Clean the surface where the plates will be placed to maximize adhesion and stability.

3. **Fitting and Securing**: Fit the plates into place and secure them using appropriate fasteners or adhesives.

Maintenance Practices

Regular maintenance practices should include:

- Routine inspections for wear and tear

- Cleaning to remove debris and contaminants

- Immediate repairs or replacements as needed

Conclusion

In conclusion, **perforated anti-slip plates** are indispensable components in the realm of metal processing. Their unique design enhances safety, boosts productivity, and provides long-term cost savings. As companies continue to prioritize efficiency and worker safety, the adoption of these plates will undoubtedly become more widespread, solidifying their role in modern manufacturing operations.

Frequently Asked Questions (FAQs)

1. What are perforated anti-slip plates made of?

Perforated anti-slip plates are typically made from durable materials like stainless steel or aluminum, which offer corrosion resistance and strength.

2. How do perforated anti-slip plates enhance safety?

These plates provide a slip-resistant surface, significantly reducing the likelihood of accidents in slippery conditions common in metal processing environments.

3. Can perforated anti-slip plates be customized for specific applications?

Yes, manufacturers can customize perforated anti-slip plates to meet the unique requirements of different machinery and work environments.

4. What maintenance is required for perforated anti-slip plates?

Regular inspections and cleaning are essential to ensure the plates remain effective. Immediate repairs or replacements should be made if wear is detected.

5. Are perforated anti-slip plates cost-effective?

Yes, while there may be an initial investment, the long-term benefits, including reduced accident-related costs and increased productivity, make them a cost-effective solution.

Key words:

RELATED INFORMATION

How Perforated Anti-Slip Plates Enhance Metal Processing Efficiency

How Perforated Anti-Slip Plates Enhance Metal Processing Efficiency

Table of Contents

Introduction to Perforated Anti-Slip Plates

The Importance of Metal Processing Efficiency

Design Features of Perforated Anti-Slip Plates

Applications in Metal Processing

Benefits of Using Perforated Anti-Slip Plates

Enhancing Workplace Safety

Cost-Effectiveness and Longevity

Insta

2025-10-17

Quality Fine Polyurethane Screen Mesh

Discover the next generation of screening efficiency with our Fine Polyurethane Screen Mesh. This advanced material is meticulously crafted to provide unparalleled accuracy in separating fine materials, setting a new standard for performance in harsh industrial conditions. Its robust polyurethane construction guarantees resilience against abrasion and chemical degradation.

2025-10-16

Understanding Perforated Anti-Slip Plates: A Key Component in Metal Fabrication

In the realm of metal processing machinery, a critical component that often goes overlooked is the perforated anti-slip plate. These plates are designed to provide a combination of structural strength, safety, and functionality, making them integral to various applications in the manufacturing sector.

Perforated anti-slip plates are flat sheets of metal that have been strategically punched with ho

2025-10-14