Understanding Perforated Anti-Slip Plates: A Key Component in Metal Fabrication

2025-10-14

In the realm of metal processing machinery, a critical component that often goes overlooked is the perforated anti-slip plate. These plates are designed to provide a combination of structural strength, safety, and functionality, making them integral to various applications in the manufacturing sector.

Perforated anti-slip plates are flat sheets of metal that have been strategically punched with ho

In the realm of metal processing machinery, a critical component that often goes overlooked is the perforated anti-slip plate. These plates are designed to provide a combination of structural strength, safety, and functionality, making them integral to various applications in the manufacturing sector.

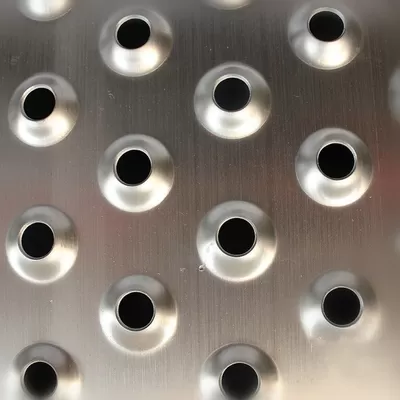

Perforated anti-slip plates are flat sheets of metal that have been strategically punched with holes. This perforation serves several purposes: it reduces the weight of the plate without compromising its strength, allows for better drainage, and enhances grip. The anti-slip feature is particularly important in environments where safety is paramount, such as factories and construction sites. By preventing slips and falls, these plates contribute significantly to workplace safety.

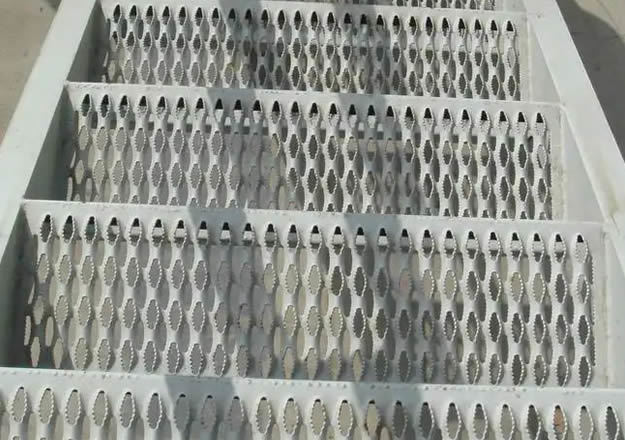

One of the primary applications of perforated anti-slip plates is in flooring systems, particularly in areas where heavy machinery is operated. The textured surface of these plates provides optimal grip for workers who are maneuvering in potentially hazardous environments. Additionally, they can be used in walkways, ramps, and platforms to ensure that personnel maintain their footing while carrying out their duties.

Another significant benefit of using perforated anti-slip plates is their versatility. They can be manufactured from various metals, including steel, aluminum, and stainless steel, which allows for customization based on specific project requirements. This adaptability makes them suitable for a wide range of industries beyond just metal processing, including automotive, construction, and aerospace.

Furthermore, the design of perforated anti-slip plates can be tailored to meet specific aesthetic or functional needs. For instance, different hole patterns can be created to provide varying levels of slip resistance or to accommodate different drainage requirements. This customization capability enables businesses to select the optimal plate for their particular application.

In addition to their safety and functional benefits, perforated anti-slip plates can also contribute to the overall efficiency of manufacturing processes. By allowing for better airflow and drainage, they can help prevent the buildup of water or debris, reducing the risk of accidents and enhancing operational efficiency.

Ultimately, incorporating perforated anti-slip plates into metal fabrication processes not only enhances safety but also supports a more efficient and productive work environment. As industries continue to prioritize safety and functionality, understanding the role of such components becomes increasingly important. By leveraging the advantages offered by these plates, manufacturers can ensure that they provide a safe and effective workplace for their employees while optimizing their operations.

In summary, perforated anti-slip plates are more than just a safety feature; they are a vital component that contributes to the overall functionality and efficiency of metal processing machinery. Understanding their applications and benefits can help businesses make informed decisions in their manufacturing processes.

Perforated anti-slip plates are flat sheets of metal that have been strategically punched with holes. This perforation serves several purposes: it reduces the weight of the plate without compromising its strength, allows for better drainage, and enhances grip. The anti-slip feature is particularly important in environments where safety is paramount, such as factories and construction sites. By preventing slips and falls, these plates contribute significantly to workplace safety.

One of the primary applications of perforated anti-slip plates is in flooring systems, particularly in areas where heavy machinery is operated. The textured surface of these plates provides optimal grip for workers who are maneuvering in potentially hazardous environments. Additionally, they can be used in walkways, ramps, and platforms to ensure that personnel maintain their footing while carrying out their duties.

Another significant benefit of using perforated anti-slip plates is their versatility. They can be manufactured from various metals, including steel, aluminum, and stainless steel, which allows for customization based on specific project requirements. This adaptability makes them suitable for a wide range of industries beyond just metal processing, including automotive, construction, and aerospace.

Furthermore, the design of perforated anti-slip plates can be tailored to meet specific aesthetic or functional needs. For instance, different hole patterns can be created to provide varying levels of slip resistance or to accommodate different drainage requirements. This customization capability enables businesses to select the optimal plate for their particular application.

In addition to their safety and functional benefits, perforated anti-slip plates can also contribute to the overall efficiency of manufacturing processes. By allowing for better airflow and drainage, they can help prevent the buildup of water or debris, reducing the risk of accidents and enhancing operational efficiency.

Ultimately, incorporating perforated anti-slip plates into metal fabrication processes not only enhances safety but also supports a more efficient and productive work environment. As industries continue to prioritize safety and functionality, understanding the role of such components becomes increasingly important. By leveraging the advantages offered by these plates, manufacturers can ensure that they provide a safe and effective workplace for their employees while optimizing their operations.

In summary, perforated anti-slip plates are more than just a safety feature; they are a vital component that contributes to the overall functionality and efficiency of metal processing machinery. Understanding their applications and benefits can help businesses make informed decisions in their manufacturing processes.

Key words:

RELATED INFORMATION

Understanding Perforated Anti-Slip Plates: A Key Component in Metal Fabrication

In the realm of metal processing machinery, a critical component that often goes overlooked is the perforated anti-slip plate. These plates are designed to provide a combination of structural strength, safety, and functionality, making them integral to various applications in the manufacturing sector.

Perforated anti-slip plates are flat sheets of metal that have been strategically punched with ho

2025-10-14

Maximizing Safety with Perforated Anti-Slip Plates in Industrial Machinery

Maximizing Safety with Perforated Anti-Slip Plates in Industrial Machinery

In the fast-paced environment of manufacturing and industrial settings, ensuring the safety of workers is paramount. The use of **perforated anti-slip plates** has emerged as a crucial solution in enhancing safety standards across various sectors. This comprehensive guide explores the significance, benefits, and best practi

2025-10-11

Enhancing Safety and Durability with Anti-Slip Perforated Stair Treads

In the realm of construction and decorative materials, safety is paramount, particularly when it comes to staircases. One effective solution that addresses this concern is the use of anti-slip perforated stair treads. These specialized treads are designed to enhance safety by providing improved traction, thereby reducing the risk of slips and falls, which are common hazards in both commercial and

2025-10-08