Maximizing Safety with Perforated Anti-Slip Plates in Industrial Machinery

2025-10-11

Maximizing Safety with Perforated Anti-Slip Plates in Industrial Machinery

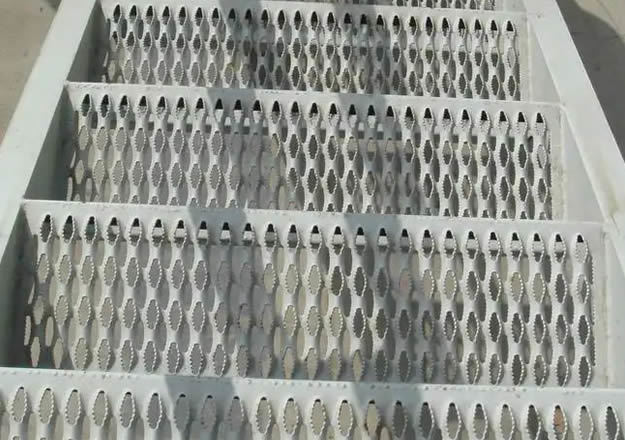

In the fast-paced environment of manufacturing and industrial settings, ensuring the safety of workers is paramount. The use of **perforated anti-slip plates** has emerged as a crucial solution in enhancing safety standards across various sectors. This comprehensive guide explores the significance, benefits, and best practices associated with the application of these plates in industrial machinery.

Understanding Perforated Anti-Slip Plates

Perforated anti-slip plates are specially designed metal sheets that feature holes or perforations. These plates are engineered to provide enhanced grip and traction, minimizing the risk of slips and falls in industrial environments. As workplaces become increasingly automated and machinery-intensive, the demand for reliable safety solutions continues to rise.

What are Perforated Anti-Slip Plates?

Perforated anti-slip plates are manufactured from various metals, including steel and aluminum. Their surface is treated to prevent corrosion and wear, ensuring durability even in high-traffic areas. The perforations in these plates serve multiple purposes: they reduce the weight of the plate while maintaining structural integrity and enhance grip by allowing better drainage of water, oil, and other slippery substances.

Importance of Safety in Industrial Machinery

Safety in industrial machinery is non-negotiable. The consequences of accidents can be severe, leading not only to injuries but also to significant financial losses for businesses. Implementing effective safety measures, such as the use of perforated anti-slip plates, is essential for creating a secure work environment. These plates play a pivotal role in maintaining operational efficiency by preventing accidents and reducing downtime.

The Benefits of Using Perforated Anti-Slip Plates

Integrating perforated anti-slip plates into industrial machinery offers a multitude of benefits. Here are some of the most significant advantages:

1. Enhanced Traction

One of the primary advantages of using perforated anti-slip plates is the **enhanced traction** they provide. The unique design of the perforations improves grip, which is crucial for operators and workers who are often in contact with machinery. This reduction in slip incidents not only promotes safety but also boosts confidence among employees.

2. Durability and Longevity

Manufactured from high-quality metals, perforated anti-slip plates are built to withstand the rigors of industrial environments. They resist wear and tear, corrosion, and other forms of damage, ensuring a long service life. Investing in durable safety solutions like these plates translates to lower replacement costs and reduced maintenance efforts.

3. Lightweight Design

The perforated design of these plates also makes them lightweight compared to solid metal sheets. This characteristic facilitates easier installation, handling, and replacement, significantly contributing to operational efficiency.

4. Easy Maintenance

Maintaining perforated anti-slip plates is straightforward. The open design allows for easy cleaning, ensuring that any build-up of substances that can cause slips is quickly removed. Regular maintenance ensures that the plates continue to function effectively over time.

5. Customizable Features

Perforated anti-slip plates are customizable to meet specific industrial needs. They can be tailored in terms of size, shape, and perforation patterns, making them suitable for a wide range of machinery and applications. This adaptability allows businesses to implement safety solutions that fit their unique operational requirements.

Applications of Perforated Anti-Slip Plates in Industrial Settings

Perforated anti-slip plates find applications across various sectors due to their versatility and effectiveness in enhancing safety. Here are some common applications:

1. Manufacturing Facilities

In manufacturing plants, where heavy machinery and equipment are common, the risk of slips and falls is significant. Anti-slip plates can be installed on walkways, platforms, and machine surfaces to provide a safer working environment.

2. Construction Sites

Construction sites often have uneven surfaces and hazardous conditions. Utilizing perforated anti-slip plates can significantly reduce the risk of accidents, especially on scaffolding and temporary structures.

3. Warehouses and Distribution Centers

In warehouses, the movement of heavy loads is a common occurrence. Anti-slip plates can be used on loading docks, ramps, and storage shelves to prevent slips, ensuring worker safety during operations.

4. Automotive Industry

The automotive sector can benefit from these plates in assembly lines and repair stations where employees frequently work in close proximity to machinery and tools. Enhanced traction reduces the risk of slips while improving productivity.

5. Food Processing Facilities

In food processing plants, maintaining hygiene is essential. Perforated anti-slip plates can be cleaned easily, providing a safe and sanitary environment for food handling and processing.

Installation of Perforated Anti-Slip Plates

Proper installation of perforated anti-slip plates is crucial to maximizing their effectiveness. Here are key steps to consider during the installation process:

1. Assess the Area

Before installation, conduct a thorough assessment of the area where the plates will be placed. Consider factors such as foot traffic, machinery type, and the likelihood of spills.

2. Choose the Right Plate

Select the appropriate perforated anti-slip plate based on the specific requirements of the environment. Consider the material, thickness, and perforation pattern needed for optimal performance.

3. Prepare the Surface

Ensure that the surface where the plates will be installed is clean, dry, and free of debris. This will help achieve a secure fit and maximize the effectiveness of the plates.

4. Secure the Plates

Use suitable fasteners to secure the plates in place. Ensure that they are firmly attached to prevent movement, which could compromise safety.

5. Regular Inspections

After installation, schedule regular inspections to assess the condition of the plates. Look for signs of wear, corrosion, or any other issues that may affect their performance.

Maintenance of Perforated Anti-Slip Plates

To ensure the longevity and effectiveness of perforated anti-slip plates, regular maintenance is essential. Here are some maintenance tips:

1. Routine Cleaning

Regularly clean the plates using appropriate cleaning solutions to remove dirt, grease, and other substances that can cause slips. Avoid using harsh chemicals that could damage the metal surface.

2. Inspect for Damage

Conduct frequent inspections to check for signs of damage, such as bent or corroded areas. Address any issues promptly to prevent further deterioration.

3. Reapply Anti-Corrosion Coating

If the plates are exposed to harsh environments, consider reapplying an anti-corrosion coating periodically to protect them from rust and degradation.

4. Monitor Traction Levels

Over time, the effectiveness of the anti-slip surface may diminish. Use traction testing methods to ensure that the plates continue to provide adequate grip and traction.

FAQs about Perforated Anti-Slip Plates

1. What materials are used to make perforated anti-slip plates?

Perforated anti-slip plates are typically made from durable metals such as aluminum or steel, which provide strength and resistance to wear and corrosion.

2. How do I choose the right perforated anti-slip plate for my application?

Consider factors such as environment, foot traffic, and specific safety requirements. Consult with suppliers to identify the best options for your needs.

3. Can perforated anti-slip plates be customized?

Yes, many manufacturers offer customization options for size, shape, and perforation patterns to suit specific industrial applications.

4. How often should I inspect my anti-slip plates?

Regular inspections should be conducted at least quarterly, or more frequently if the area experiences heavy traffic or harsh conditions.

5. Are there any regulations regarding the use of anti-slip plates in industrial settings?

Yes, various safety regulations exist that mandate the use of anti-slip materials in specific industrial environments. Always consult local safety regulations to ensure compliance.

Conclusion

Incorporating **perforated anti-slip plates** into industrial machinery is a proactive step toward enhancing safety and efficiency in the workplace. These plates not only provide the necessary traction to prevent slips and falls but also offer durability and ease of maintenance that make them an excellent investment for businesses across various sectors. By understanding their applications, installation, and maintenance best practices, companies can create a safer working environment that protects their most valuable asset—their employees.

Key words:

RELATED INFORMATION

Maximizing Safety with Perforated Anti-Slip Plates in Industrial Machinery

2025-10-11

Enhancing Safety and Durability with Anti-Slip Perforated Stair Treads

2025-10-08

Why Choosing Anti-Slip Perforated Stair Treads is Essential for Safety

2025-10-05