Understanding the Importance of Wear-Resistant Anti-Slip Perforated Plates in Metal Processing

2025-09-26

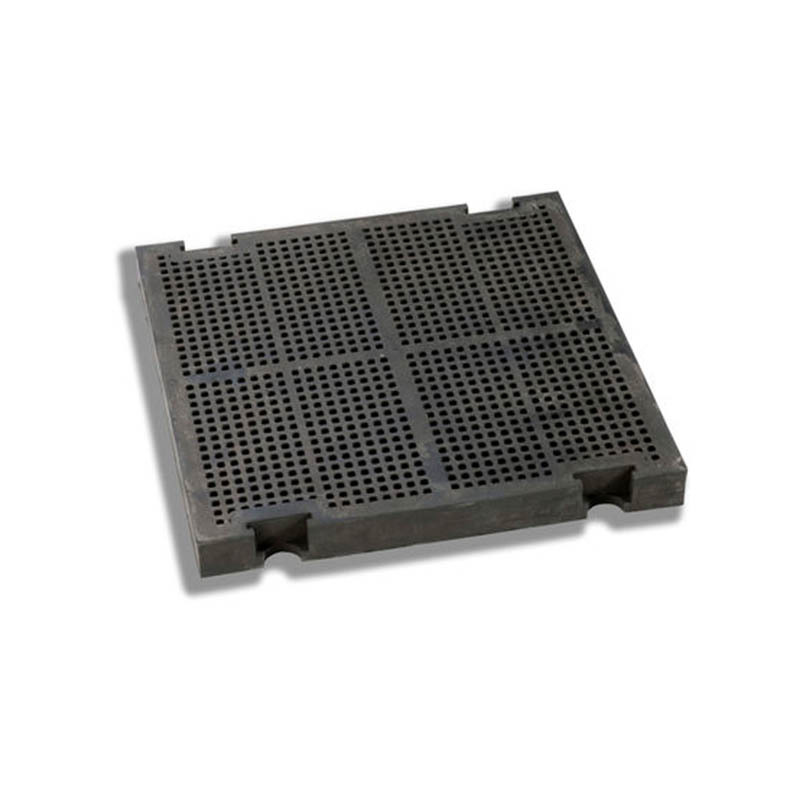

In the realm of manufacturing and metal processing, the components used directly influence the efficiency and safety of operations. One such vital component is the wear-resistant anti-slip perforated plate. These plates are designed to withstand harsh conditions while providing a secure surface for workers and machinery. Let’s delve into the characteristics, benefits, and applications of these pla

In the realm of manufacturing and metal processing, the components used directly influence the efficiency and safety of operations. One such vital component is the wear-resistant anti-slip perforated plate. These plates are designed to withstand harsh conditions while providing a secure surface for workers and machinery. Let’s delve into the characteristics, benefits, and applications of these plates.

Wear-resistant anti-slip perforated plates feature a unique design that combines durability with safety. The wear-resistant aspect ensures that these plates can endure significant mechanical stress and abrasion, making them ideal for environments where heavy machinery is in operation. For instance, in metal processing facilities where cutting, grinding, or machining takes place, these plates help maintain structural integrity, reducing the frequency of replacements and maintenance costs.

The anti-slip feature is equally crucial. Safety is paramount in any manufacturing environment, and surfaces that present trip hazards can lead to accidents and injuries. The anti-slip qualities of these perforated plates provide employees with a secure footing, which is especially important in areas where liquids or metal shavings can make surfaces slick. The perforations themselves also contribute to this safety feature by allowing debris and liquids to drain through, further reducing the risk of slips and falls.

Applications of wear-resistant anti-slip perforated plates extend beyond flooring. They are often utilized in various machinery components and equipment, such as conveyor systems, work platforms, and protective barriers. The versatility of these plates means they can be customized to fit specific needs, whether it’s for heavy-duty environments or lighter applications.

Moreover, the design of perforated plates often allows for better airflow and cooling, which can be essential in processes that generate heat. This characteristic helps maintain optimal operating temperatures for machinery, thereby enhancing performance and extending equipment lifespan.

In conclusion, wear-resistant anti-slip perforated plates are indispensable in the metal processing industry. Their robust nature and safety features significantly contribute to a safer working environment, while their versatility allows for diverse applications across various machinery and components. Investing in high-quality perforated plates not only improves operational efficiency but also fosters a culture of safety within the workplace, making them an essential consideration for any manufacturing operation.

Wear-resistant anti-slip perforated plates feature a unique design that combines durability with safety. The wear-resistant aspect ensures that these plates can endure significant mechanical stress and abrasion, making them ideal for environments where heavy machinery is in operation. For instance, in metal processing facilities where cutting, grinding, or machining takes place, these plates help maintain structural integrity, reducing the frequency of replacements and maintenance costs.

The anti-slip feature is equally crucial. Safety is paramount in any manufacturing environment, and surfaces that present trip hazards can lead to accidents and injuries. The anti-slip qualities of these perforated plates provide employees with a secure footing, which is especially important in areas where liquids or metal shavings can make surfaces slick. The perforations themselves also contribute to this safety feature by allowing debris and liquids to drain through, further reducing the risk of slips and falls.

Applications of wear-resistant anti-slip perforated plates extend beyond flooring. They are often utilized in various machinery components and equipment, such as conveyor systems, work platforms, and protective barriers. The versatility of these plates means they can be customized to fit specific needs, whether it’s for heavy-duty environments or lighter applications.

Moreover, the design of perforated plates often allows for better airflow and cooling, which can be essential in processes that generate heat. This characteristic helps maintain optimal operating temperatures for machinery, thereby enhancing performance and extending equipment lifespan.

In conclusion, wear-resistant anti-slip perforated plates are indispensable in the metal processing industry. Their robust nature and safety features significantly contribute to a safer working environment, while their versatility allows for diverse applications across various machinery and components. Investing in high-quality perforated plates not only improves operational efficiency but also fosters a culture of safety within the workplace, making them an essential consideration for any manufacturing operation.

Key words:

RELATED INFORMATION

Understanding the Importance of Wear-Resistant Anti-Slip Perforated Plates in Metal Processing

In the realm of manufacturing and metal processing, the components used directly influence the efficiency and safety of operations. One such vital component is the wear-resistant anti-slip perforated plate. These plates are designed to withstand harsh conditions while providing a secure surface for workers and machinery. Let’s delve into the characteristics, benefits, and applications of these pla

2025-09-26