How Anti-Slip Technology in Perforated Plates Revolutionizes Metal Processing

2025-09-23

How Anti-Slip Technology in Perforated Plates Revolutionizes Metal Processing

Introduction to Anti-Slip Technology

In the ever-evolving world of **metal processing**, ensuring safety and efficiency is paramount. One of the most groundbreaking innovations in this field is **anti-slip technology** integrated into **perforated plates**. This technology not only enhances safety during operations but a

How Anti-Slip Technology in Perforated Plates Revolutionizes Metal Processing

Introduction to Anti-Slip Technology

In the ever-evolving world of **metal processing**, ensuring safety and efficiency is paramount. One of the most groundbreaking innovations in this field is **anti-slip technology** integrated into **perforated plates**. This technology not only enhances safety during operations but also improves overall productivity. As we delve deeper into this topic, we will explore the mechanics behind anti-slip technology, its applications, and the significant impact it has on the metal processing industry.

Understanding Perforated Plates and Their Functionality

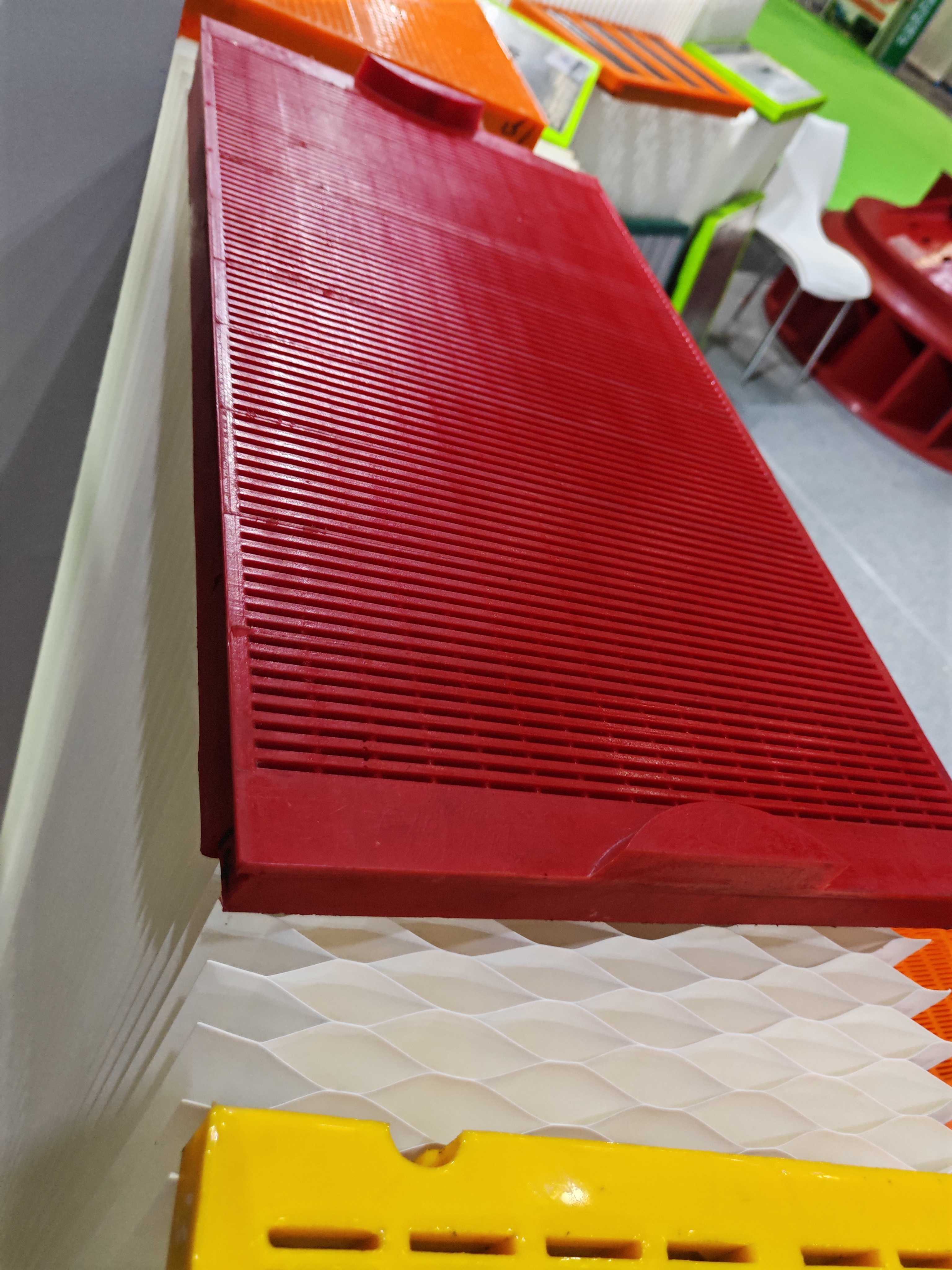

Perforated plates are essential components in various metal processing applications. These plates, featuring a series of holes or slots, play a crucial role in multiple processes, including filtration, separation, and support structures. Their design allows for the efficient flow of materials while maintaining structural integrity.

The Importance of Anti-Slip Technology

In any industrial setting, the risk of slips and falls is prevalent, especially in areas where workers interact with heavy machinery and materials. **Anti-slip technology** addresses these risks by providing enhanced traction on perforated surfaces. This technology is particularly vital in environments where wet or oily conditions are common, significantly reducing the likelihood of accidents.

Mechanics Behind Anti-Slip Technology

Anti-slip technology typically involves the application of specialized coatings or surface treatments that increase the friction coefficient of perforated plates. These enhancements ensure that materials remain stable, reducing the risk of slippage during processing.

Types of Anti-Slip Solutions

There are several methods through which anti-slip properties can be achieved, including:

1. Texturing Surfaces

By creating textured finishes on perforated plates, manufacturers can significantly increase the surface area, which enhances grip. This method is particularly effective in preventing slippage.

2. Coatings and Treatments

Various coatings, such as rubberized overlays or chemical treatments, can be applied to the surface of perforated plates. These coatings increase friction and durability, making them ideal for demanding environments.

3. Material Selection

Using specific materials with inherent anti-slip properties can also contribute to the overall effectiveness of perforated plates in preventing slippage. For instance, certain metals and composites can be designed to offer better grip.

Applications of Anti-Slip Perforated Plates in Metal Processing

The integration of anti-slip technology in perforated plates has a wide range of applications within the metal processing industry. Here are some notable examples:

1. Conveyor Systems

In conveyor systems, anti-slip perforated plates help securely transport materials, preventing them from sliding off during movement. This feature is crucial in maintaining efficiency and safety in material handling.

2. Work Platforms

Many metal processing operations involve elevated work platforms where workers perform tasks. Anti-slip perforated plates provide a safer work environment, minimizing the risk of falls.

3. Industrial Flooring

In manufacturing facilities, anti-slip perforated plates can be used as flooring solutions, particularly in areas prone to spills or heavy foot traffic. Such installations maximize safety without compromising structural integrity.

4. Railing Systems

Railing systems that incorporate anti-slip technology enhance safety by providing better grip for workers handling materials at heights.

5. Support Structures

Perforated plates serve as support structures in various machines and equipment. The anti-slip feature ensures that components remain secure during operation, reducing wear and tear.

Benefits of Implementing Anti-Slip Technology in Metal Processing

Adopting anti-slip technology in perforated plates offers several key benefits:

1. Enhanced Safety

The primary advantage of anti-slip perforated plates is the significant reduction in workplace accidents. By minimizing the risk of slips and falls, companies can create a safer working environment for all employees.

2. Increased Productivity

With improved safety measures in place, workers can focus on their tasks without the constant worry of accidents. This heightened concentration leads to increased productivity and efficiency in metal processing operations.

3. Cost-Effectiveness

Investing in anti-slip technology can lead to long-term cost savings. Fewer accidents mean reduced medical expenses and lower insurance premiums. Additionally, durable anti-slip perforated plates can decrease maintenance costs associated with equipment and materials.

4. Compliance with Safety Regulations

Many industries are subject to strict safety regulations. By implementing anti-slip technology, companies can better comply with these standards, avoiding potential legal issues and penalties.

Challenges and Considerations in Implementing Anti-Slip Technology

While the benefits are substantial, there are challenges and considerations to keep in mind when integrating anti-slip technology into perforated plates.

1. Initial Investment Costs

The cost of acquiring anti-slip perforated plates may be higher than traditional options. However, companies should consider the long-term savings associated with reduced accidents and maintenance.

2. Selection of Appropriate Technology

Not all anti-slip solutions are suitable for every application. It is crucial to evaluate the specific needs of the operation to select the most effective technology.

3. Maintenance and Longevity

Regular maintenance is essential to ensure the effectiveness of anti-slip features. Companies should develop a routine inspection and maintenance plan to prolong the lifespan of these plates.

Future Trends in Anti-Slip Technology for Metal Processing

As technology continues to advance, several trends are emerging in the realm of anti-slip technology for perforated plates.

1. Smart Materials

The development of smart materials that can adapt to varying conditions is an exciting trend. These materials may incorporate sensors that adjust anti-slip properties based on environmental factors.

2. Advanced Surface Treatments

Research into more effective surface treatments that enhance durability and anti-slip characteristics is ongoing. These advancements will likely lead to even more robust solutions for the metal processing industry.

3. Sustainable Solutions

With growing environmental concerns, the industry is moving toward sustainable materials and processes. Future anti-slip technologies may focus on eco-friendly options without compromising safety.

FAQs About Anti-Slip Technology in Perforated Plates

1. What is anti-slip technology?

Anti-slip technology refers to methods and materials designed to increase surface friction, reducing the likelihood of slips and falls.

2. How do anti-slip perforated plates improve safety?

By enhancing traction on surfaces, anti-slip perforated plates provide a safer working environment, particularly in areas prone to spills and heavy foot traffic.

3. Are there specific industries that benefit more from anti-slip technology?

Yes, industries such as manufacturing, construction, and warehousing, where heavy machinery and materials are involved, greatly benefit from anti-slip technology.

4. How can I choose the right anti-slip solution for my application?

Evaluate your specific operational needs and conditions, considering factors such as the type of materials handled and the environment in which the plates will be used.

5. What maintenance is required for anti-slip perforated plates?

Regular inspections and cleaning are essential to maintain the effectiveness of anti-slip features. Companies should develop a maintenance schedule to ensure safety.

Conclusion

In summary, anti-slip technology in perforated plates is a transformative advancement in the metal processing industry. By enhancing safety, increasing productivity, and offering cost-effective solutions, this technology is setting new standards for operational excellence. As we continue to innovate, the future of metal processing looks promising, with further advancements in anti-slip solutions paving the way for safer and more efficient operations. Embracing this technology will undoubtedly contribute to a more secure working environment, ultimately benefiting workers and manufacturers alike.

Key words:

RELATED INFORMATION

How Anti-Slip Technology in Perforated Plates Revolutionizes Metal Processing

How Anti-Slip Technology in Perforated Plates Revolutionizes Metal Processing

Introduction to Anti-Slip Technology

In the ever-evolving world of **metal processing**, ensuring safety and efficiency is paramount. One of the most groundbreaking innovations in this field is **anti-slip technology** integrated into **perforated plates**. This technology not only enhances safety during operations but a

2025-09-23