Understanding the Importance of Corrosion-Resistant Grating in Chemical Plants

2025-09-20

Corrosion is a significant challenge faced by chemical plants due to the presence of harsh chemicals and extreme environmental conditions. Traditional materials may quickly deteriorate, posing safety risks and increasing maintenance costs. This is where corrosion-resistant grating comes into play, offering a solution that enhances durability and longevity for various applications within the plant.

Corrosion is a significant challenge faced by chemical plants due to the presence of harsh chemicals and extreme environmental conditions. Traditional materials may quickly deteriorate, posing safety risks and increasing maintenance costs. This is where corrosion-resistant grating comes into play, offering a solution that enhances durability and longevity for various applications within the plant.

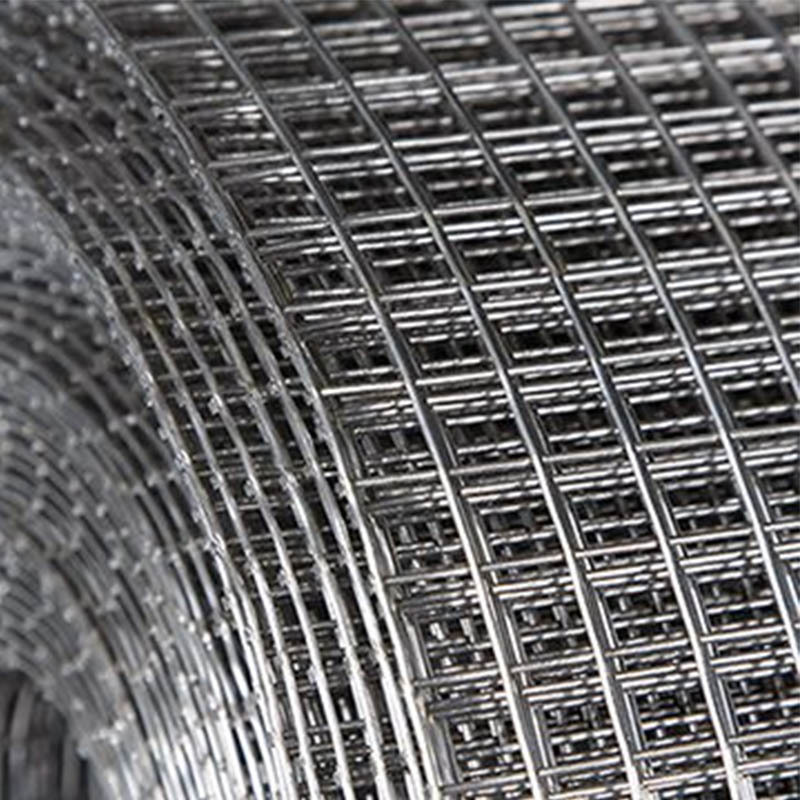

Corrosion-resistant grating is typically manufactured from materials such as fiberglass reinforced plastic (FRP) or stainless steel, both of which provide excellent resistance to corrosive environments. FRP grating, for instance, is lightweight yet strong, making it easy to install while ensuring it can withstand heavy loads. Its non-conductive properties also make it an ideal choice in facilities where electrical safety is a concern.

The applications of corrosion-resistant grating in chemical plants are extensive. It is commonly utilized in walkways, platforms, and staircases, ensuring that personnel can navigate the facility safely, even in the presence of spills or leaks. Additionally, it is often used in drainage systems to prevent the buildup of corrosive substances that could lead to operational issues.

In terms of maintenance, one of the most significant advantages of corrosion-resistant grating is its low upkeep requirements. Unlike traditional metal grates that may require regular painting or treatment to prevent rust and corrosion, these specialized materials can often be cleaned with simple detergents and do not need any additional protective coatings. This feature not only saves time and resources but also minimizes disruption to plant operations.

Furthermore, investing in corrosion-resistant grating can lead to long-term cost savings. While the initial investment might be higher than conventional materials, the reduction in replacement costs and maintenance efforts can result in significant financial benefits over the lifespan of the grating.

In summary, corrosion-resistant grating is an essential component of chemical plants, providing safety, durability, and cost-effectiveness. By choosing the right materials, plant operators can ensure a safer working environment while minimizing the risks associated with corrosion. As the industry continues to evolve, understanding the benefits and applications of such specialized materials will be key to maintaining operational efficiency and integrity in chemical processing facilities.

Corrosion-resistant grating is typically manufactured from materials such as fiberglass reinforced plastic (FRP) or stainless steel, both of which provide excellent resistance to corrosive environments. FRP grating, for instance, is lightweight yet strong, making it easy to install while ensuring it can withstand heavy loads. Its non-conductive properties also make it an ideal choice in facilities where electrical safety is a concern.

The applications of corrosion-resistant grating in chemical plants are extensive. It is commonly utilized in walkways, platforms, and staircases, ensuring that personnel can navigate the facility safely, even in the presence of spills or leaks. Additionally, it is often used in drainage systems to prevent the buildup of corrosive substances that could lead to operational issues.

In terms of maintenance, one of the most significant advantages of corrosion-resistant grating is its low upkeep requirements. Unlike traditional metal grates that may require regular painting or treatment to prevent rust and corrosion, these specialized materials can often be cleaned with simple detergents and do not need any additional protective coatings. This feature not only saves time and resources but also minimizes disruption to plant operations.

Furthermore, investing in corrosion-resistant grating can lead to long-term cost savings. While the initial investment might be higher than conventional materials, the reduction in replacement costs and maintenance efforts can result in significant financial benefits over the lifespan of the grating.

In summary, corrosion-resistant grating is an essential component of chemical plants, providing safety, durability, and cost-effectiveness. By choosing the right materials, plant operators can ensure a safer working environment while minimizing the risks associated with corrosion. As the industry continues to evolve, understanding the benefits and applications of such specialized materials will be key to maintaining operational efficiency and integrity in chemical processing facilities.

Key words:

RELATED INFORMATION

Understanding the Importance of Corrosion-Resistant Grating in Chemical Plants

Corrosion is a significant challenge faced by chemical plants due to the presence of harsh chemicals and extreme environmental conditions. Traditional materials may quickly deteriorate, posing safety risks and increasing maintenance costs. This is where corrosion-resistant grating comes into play, offering a solution that enhances durability and longevity for various applications within the plant.

2025-09-20