Understanding the Importance of Corrosion-Resistant Grating in Chemical Plants

2025-09-17

Understanding the Importance of Corrosion-Resistant Grating in Chemical Plants

Table of Contents

1. Introduction to Corrosion-Resistant Grating

2. The Challenges of Corrosion in Chemical Plants

3. Types of Corrosion-Resistant Grating Materials

4. Benefits of Using Corrosion-Resistant Grating

5. Installation Techniques for Corrosion-Resistant Grating

6. Maintenance Practice

Understanding the Importance of Corrosion-Resistant Grating in Chemical Plants

Table of Contents

- 1. Introduction to Corrosion-Resistant Grating

- 2. The Challenges of Corrosion in Chemical Plants

- 3. Types of Corrosion-Resistant Grating Materials

- 4. Benefits of Using Corrosion-Resistant Grating

- 5. Installation Techniques for Corrosion-Resistant Grating

- 6. Maintenance Practices for Longevity

- 7. Case Studies: Successful Implementations

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Corrosion-Resistant Grating

In the chemical industry, the use of **corrosion-resistant grating** is paramount. As facilities operate with harsh chemicals that can rapidly degrade materials, the choice of flooring and platforms becomes critical. **Corrosion-resistant grating** not only enhances safety by preventing slips and falls but also supports the structural integrity of chemical plants over time. This article delves deep into the relevance of these materials, helping stakeholders understand their importance in industrial settings.

2. The Challenges of Corrosion in Chemical Plants

Chemical plants face unique challenges due to the presence of corrosive substances. **Corrosion** can lead to costly downtime, safety hazards, and even environmental disasters. Here are key issues associated with corrosion in these facilities:

2.1 Financial Implications of Corrosion

Corrosion-related failures can result in significant financial losses. According to various studies, the cost of corrosion to the U.S. economy is estimated to be over $300 billion annually. For chemical plants, unplanned maintenance and replacements can drain budgets, diverting funds from other crucial projects.

2.2 Safety Hazards

The risks associated with corrosion extend beyond financial concerns. Structural failures can lead to catastrophic accidents, putting workers' lives at risk. Using inferior materials that corrode easily can mean the difference between a safe work environment and a potential disaster.

2.3 Regulatory Compliance Challenges

Chemical plants are subject to rigorous safety regulations. Failing to implement corrosion-resistant solutions may lead to non-compliance, resulting in fines and legal repercussions.

3. Types of Corrosion-Resistant Grating Materials

The selection of grating material plays a vital role in combating corrosion. Several types of materials are known for their durability and resistance to corrosive agents:

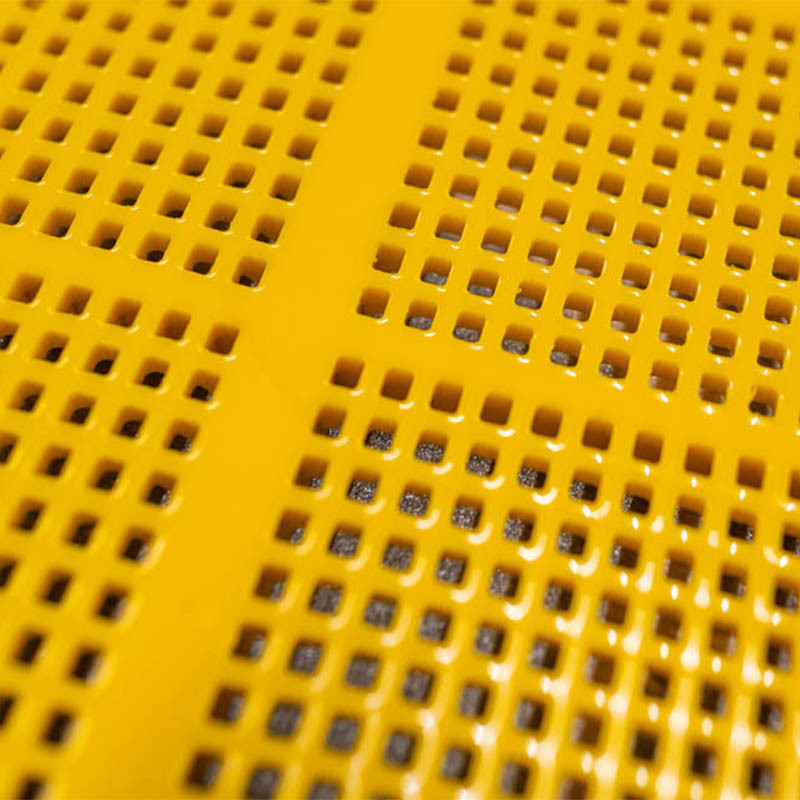

3.1 Fiberglass Reinforced Plastic (FRP)

FRP grating is lightweight, strong, and resistant to a variety of chemical agents. It does not rust or corrode, making it ideal for environments with high moisture or exposure to harsh chemicals.

3.2 Stainless Steel

A popular choice for industrial applications, stainless steel grating offers excellent strength and corrosion resistance. It is particularly effective in environments where high temperatures and pressures are present.

3.3 Aluminum

Aluminum grating is another excellent option due to its lightweight nature and corrosion resistance. It is often used in environments where weight reduction is a priority, such as in offshore platforms.

3.4 Plastic Grating

Plastic grating offers cost-effective solutions for less corrosive environments. It is resistant to many chemicals and is typically used in areas where chemical exposure is sporadic.

4. Benefits of Using Corrosion-Resistant Grating

Utilizing corrosion-resistant grating brings numerous advantages:

4.1 Enhanced Safety

By preventing corrosion-related hazards, these gratings contribute significantly to worker safety. Their slip-resistant surfaces ensure stability in even the most challenging conditions.

4.2 Reduced Maintenance Costs

Less frequent replacements of grating systems lead to lower maintenance costs. Facilities can allocate budgets more effectively, supporting overall operational efficiency.

4.3 Extended Lifespan

Corrosion-resistant materials generally boast a longer lifespan compared to traditional grating options. This longevity translates to fewer disruptions and enhanced productivity.

4.4 Environmental Considerations

Using sustainable materials that resist corrosion helps minimize environmental impact. This approach aligns with global sustainability goals and enhances a company's reputation.

5. Installation Techniques for Corrosion-Resistant Grating

Proper installation is critical to maximizing the performance of corrosion-resistant grating systems.

5.1 Site Preparation

Before installation, thorough site preparation is essential. This includes assessing the surface and ensuring it is clean and free of debris.

5.2 Selecting the Right Fasteners

Utilizing fasteners that match the grating material is crucial. For instance, stainless steel fasteners should be used with stainless steel grating to avoid galvanic corrosion.

5.3 Ensuring Adequate Drainage

Proper drainage systems should be in place to prevent water accumulation, which can exacerbate corrosion. Grating should be installed with slight slopes to direct water away effectively.

5.4 Regular Inspections Post-Installation

Conducting inspections after installation can help identify potential issues early, ensuring longevity and safety.

6. Maintenance Practices for Longevity

To ensure the durability of corrosion-resistant grating, regular maintenance is essential.

6.1 Scheduled Inspections

Establishing a routine inspection schedule allows for early detection of wear and tear, facilitating timely repairs.

6.2 Cleaning Protocols

A regular cleaning regimen is vital to prevent the buildup of harmful substances that can lead to corrosion. Using appropriate cleaning agents that do not harm the grating material is important.

6.3 Addressing Damage Promptly

Any observed damage should be addressed immediately to prevent escalation. Repairing or replacing damaged sections ensures the overall integrity of the grating system.

7. Case Studies: Successful Implementations

Exploring real-world implementations of corrosion-resistant grating highlights its significance in various chemical plants.

7.1 Case Study: XYZ Chemical Plant

At XYZ Chemical Plant, the transition to FRP grating resulted in a 50% reduction in maintenance costs over five years. The installation minimized safety incidents, creating a more secure working environment.

7.2 Case Study: ABC Manufacturing Facility

ABC Manufacturing Facility faced significant corrosion issues with their existing steel grating. After switching to stainless steel, the facility reported improved production efficiency and compliance with safety regulations.

8. Conclusion

The importance of **corrosion-resistant grating** in chemical plants cannot be overstated. As the industry continues to evolve, embracing advanced materials and installation techniques will enhance safety, reduce costs, and promote sustainable practices. By prioritizing corrosion resistance, chemical plants can safeguard their operations, protect their workers, and ensure compliance with regulatory standards.

9. Frequently Asked Questions

9.1 What is corrosion-resistant grating?

Corrosion-resistant grating is a type of flooring or platform material designed to withstand harsh chemical environments without degrading. It is essential for safety and durability in chemical plants.

9.2 How long does corrosion-resistant grating last?

The lifespan of corrosion-resistant grating varies by material. FRP can last 20-30 years, while stainless steel may last even longer with proper maintenance.

9.3 What are the common materials used for corrosion-resistant grating?

Common materials include fiberglass reinforced plastic (FRP), stainless steel, aluminum, and various plastics, each offering unique benefits based on the operational environment.

9.4 How can I maintain corrosion-resistant grating?

Regular inspections, cleaning, and prompt repairs are crucial for maintaining the integrity and functionality of corrosion-resistant grating.

9.5 What are the costs associated with installing corrosion-resistant grating?

While initial costs can be higher than traditional materials, the long-term savings in maintenance and enhanced safety often outweigh these initial expenses.

Key words:

RELATED INFORMATION

Understanding the Importance of Corrosion-Resistant Grating in Chemical Plants

Understanding the Importance of Corrosion-Resistant Grating in Chemical Plants

Table of Contents

1. Introduction to Corrosion-Resistant Grating

2. The Challenges of Corrosion in Chemical Plants

3. Types of Corrosion-Resistant Grating Materials

4. Benefits of Using Corrosion-Resistant Grating

5. Installation Techniques for Corrosion-Resistant Grating

6. Maintenance Practice

2025-09-17