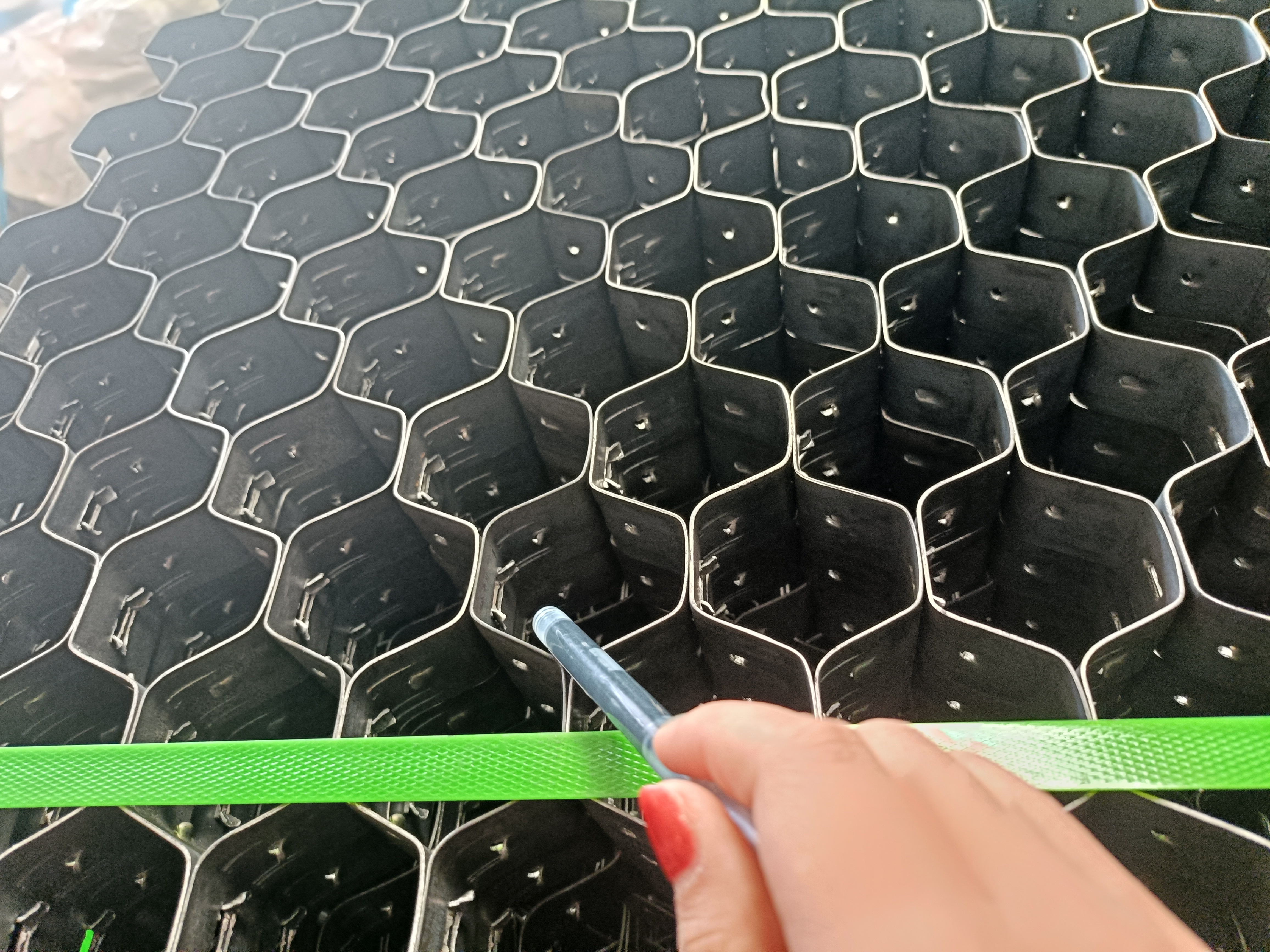

High-temperature lined hexagonal mesh helps Czech power plant cope with wear and tear at gas conveying elbows

2025-06-20

Due to severe wear and tear at the elbows of pneumatic conveying pipes due to material steering, the Czech power plant adopted a variable-diameter hexagonal mesh design, with an encapsulated mesh and thicker wear-resistant coating at the elbows, and a parabolic infusion structure to optimize the material flow. The parabolic flow structure optimizes the material flow. After the application in the Havijov regional power plant, the elbow wear was reduced by 90% and the replacement cycle was extended from 8 months to 3 years.

Key words:

RELATED INFORMATION

Understanding Ladder Perforated Stair Treads: Safety and Design Essentials

2025-12-11

STEEL GRATING — HIGH-STRENGTH, SAFE, AND RELIABLE INDUSTRIAL FLOORING SOLUTION

2025-12-08

Enhance Safety with Ladder Perforated Stair Treads: A Comprehensive Guide

2025-12-06