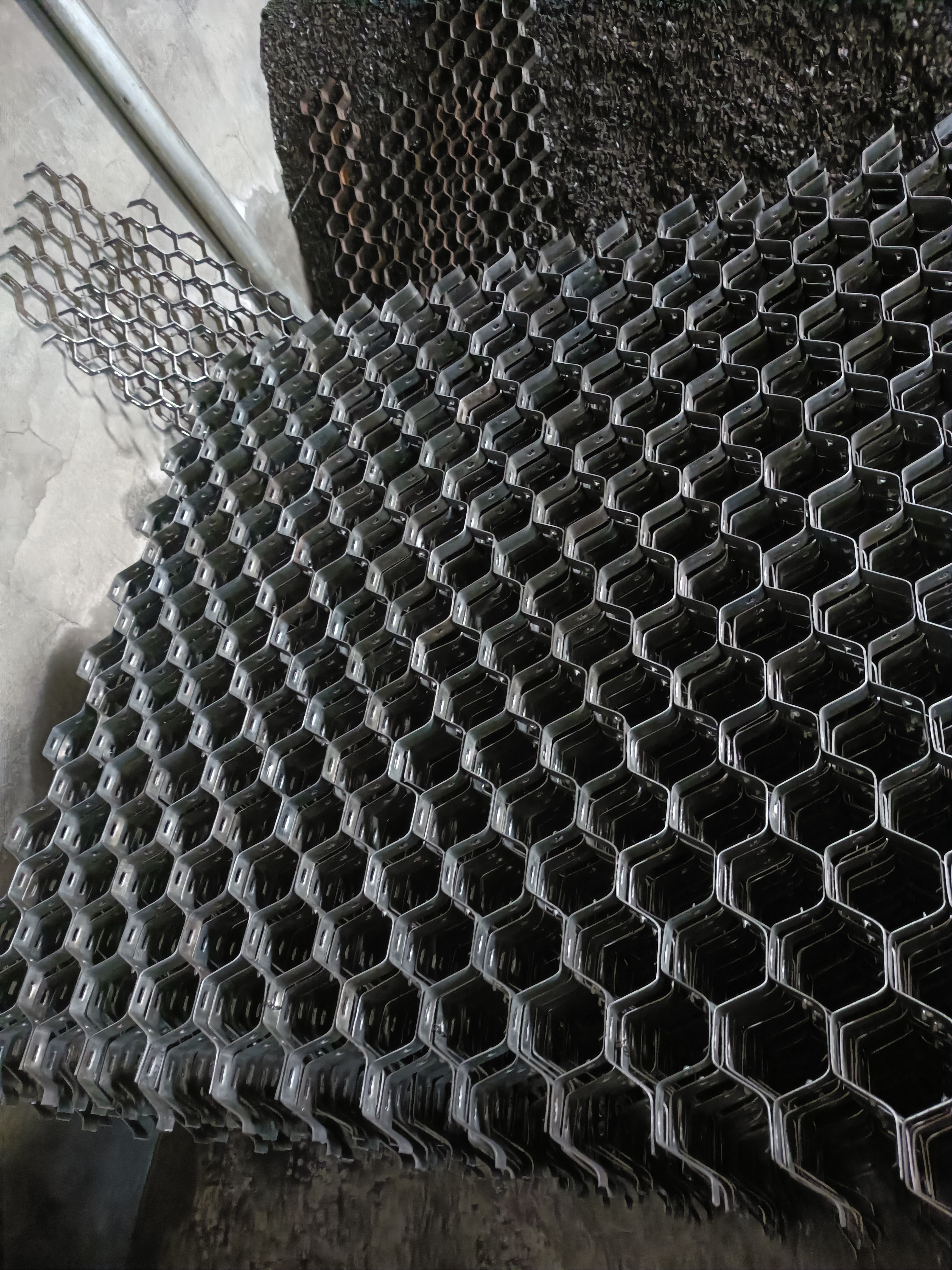

High-temperature lined hexagonal mesh solves waste incinerator wear at Czech power plant

2025-06-19

High-temperature fly ash and corrosive gases generated by waste incineration accelerate the wear of the furnace wall. The Czech power plant uses a double-layer hexagonal mesh structure with an inner layer of corrosion-resistant alloy and an outer layer of high-hardness ceramic coating, and a three-dimensional mesh that strengthens the bonding with the refractory material. After application at the Brno waste incineration plant, wall wear was reduced by 75% and maintenance intervals were extended by four times.

Key words:

RELATED INFORMATION

Understanding Ladder Perforated Stair Treads: Safety and Design Essentials

2025-12-11

STEEL GRATING — HIGH-STRENGTH, SAFE, AND RELIABLE INDUSTRIAL FLOORING SOLUTION

2025-12-08

Enhance Safety with Ladder Perforated Stair Treads: A Comprehensive Guide

2025-12-06